We offer CNC machining of ferrous and non-ferrous metals, production of parts and components for single-purpose machinery, and components for the automotive, mechanical engineering and food industries.

We are capable of prototyping, piece production and serial production. Finished parts are then packaged and labelled directly in our facility.

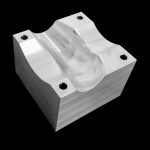

METAL WORKPIECES

- production of workpieces from steel, stainless steel, aluminium and alloys

- delivery of small orders within 7 days

- precise CNC processing

- Metal and Plastic Machining

ELECTRO-EROSIVE WIRE CUTTING

- production from steel, stainless steel, aluminium and alloys

- accuracy up to 0.005 mm and surface roughness up to Ra 0.3

- axis travel x=600, y=400, z=270

- electro-erosive cutting

Machinery for Machining and Wire-Cutting of Metals

Trimill VU 3019 – VERTICAL MILLING MACHINES (5 AXIS)

Basic technical parameters:

- longitudinal travel X: 3 000 mm(5axis), 1 950 mm(3axis)

- transverse travel Y: 1 950 mm

- vertical travel Z : 1 000 mm

- table size: ø 2300 mm

- positioning accuracy: 0,008 mm

- max. workpiece weight: 30 000 kg

Hermle C400 – VERTICAL MILLING MACHINES (5 AXIS)

Basic technical parameters:

- longitudinal travel X: 850 mm

- transverse travel Y: 700 mm

- vertical travel Z : 500 mm

- table size: ø 650 mm

- positioning accuracy: 0,008 mm

- max. workpiece weight: 600 kg

Trimill VC 1110 – VERTICAL MILLING MACHINES (3 AXIS)

Basic technical parameters:

- longitudinal travel X: 1 100 mm

- transverse travel Y: 1 000 mm

- vertical travel Z : 700 mm

- positioning accuracy: 0,008 mm

- max. workpiece weight: 8 000 kg

HARTFORD LG-1000AP (3 axis) vertical machining centre

Basic technical parameters::

- longitudinal travel X: 1 000 mm

- transverse travel Y: 510 mm

- vertical travel Z : 630 mm

- positioning accuracy: 0,01 mm

- max. workpiece weight: 700 kg

BIGLIA B1250 SM CNC LATHE (2 spindles)

Basic technical parameters:

- maximum turning length: 1.170 mm

- maximum turning diameter: 552 mm

- bar turning diameter: 100 mm

- positioning accuracy: 0,001 mm

SODICK VL600Q EDM wire cutter

Basic technical parameters:

- longitudinal travel X: 600 mm

- transverse travel Y: 400 mm

- vertical travel Z: 270 mm

- positioning accuracy: 0,005 mm

- max. workpiece weight: 850 kg